Greenhouses require a few things to function efficiently. Including open space, temperature control, durability, and more. Metal panels not only meet, but exceed these needs. Making them the perfect option for a greenhouse building.

Metal Panels Are Durable

The interior of a greenhouse is often humid, leading to building systems breaking down prematurely. Luckily, a galvanized metal building can stand its own against the moisture and the day to day rigors of a commercial growing operation.

Metal Buildings Are Column Free

Greenhouses need wide, open spaces to effectively support crops and store water. The column-free interior of a metal building allows all of these functions to take place while simultaneously providing flexibility in the layout of the space.

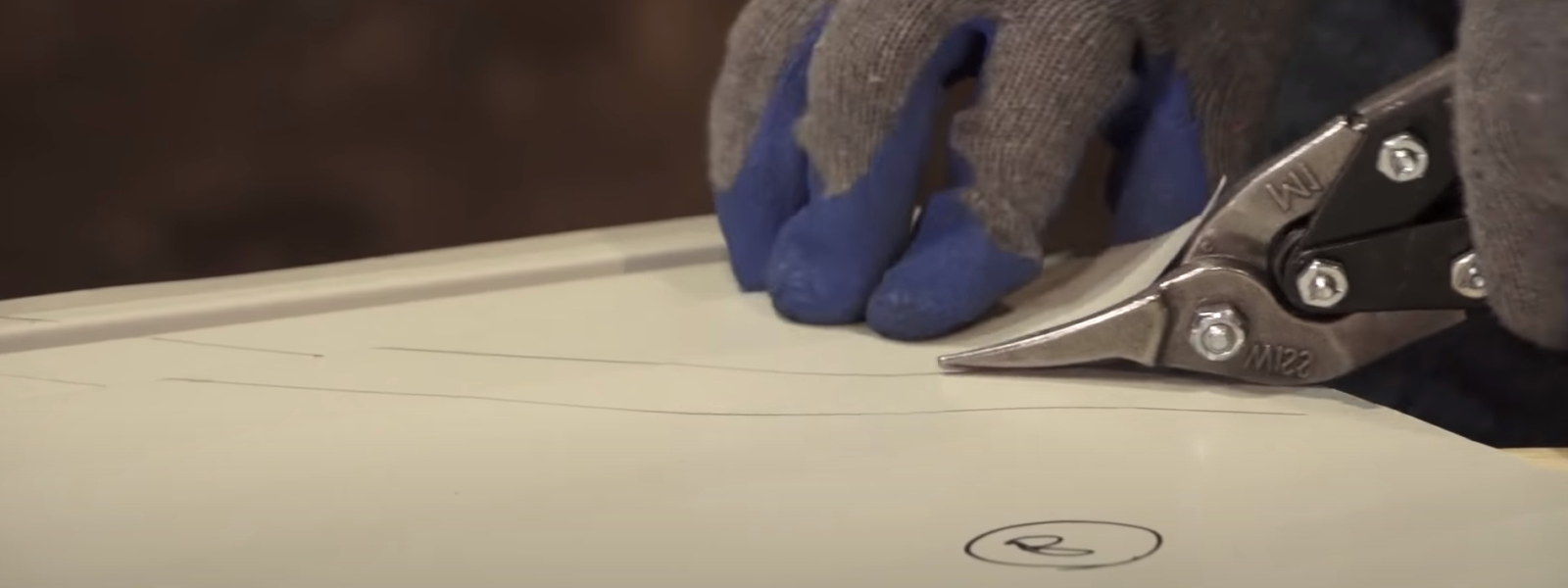

Metal Panels Are Easily Adapted To Let In Sunlight

It goes without saying that the more sunlight, the better the crops. Glazing panels can easily be integrated with the profiles of a metal building structure to allow more natural light in.

Metal Panels Are Great For Temperature Control

While the areas facing the sun are glazed, other areas may need to be insulated to protect the plants from unwanted heat and cold. Rather than just relying on a supplemental heating or cooling system, the opaque areas of a greenhouse can be designed and installed using insulated metal panels to provide a durable and energy saving component that helps keep temperatures in check.

Not only are metal panels easy to install, but easily expandable as well! As your plants and your business continue to grow, so can the building. These eco-friendly panels are an exceptional option when it comes to your greenhouse structure. Have more questions? Our qualified team of professionals would be happy to help you! Contact us today at 519-451-7663 or info@ecoinsulatedpanels.com.