May be one of the most frequently asked questions regarding metal roofs. “Are metal roofs noisy?” Well. Individuals who are looking for the solace of a gentle rain on their new metal roof could be disappointed. The theory that a metal roof is “noisy” stems from the memory of a barn, where there is nothing between an individual and the roof except air. So what make the metal roofs today different?

How Metal Roofs Today Aren’t Noisey

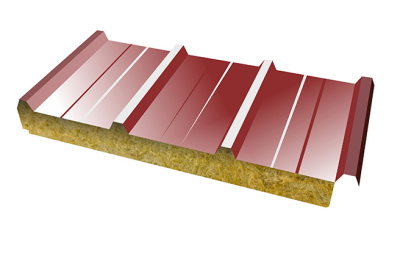

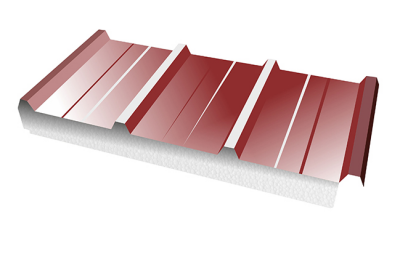

It is with few exceptions that modern metal roofing is installed without some form of underlying material that absorbs sound. And in a re-roofing situation, metal is often installed over an existing layer or two of shingles. So when you consider the multiple layers of shingles, roof deck, attic air space and the insulation above the ceiling…it’s hard to believe a homeowner could hear anything at all!

What If I Like The Sound of Rain?

A metal roof installed over open framing will register a louder sound than panels that are installed over a solid roof deck. This is because the roof deck literally absorbs or muffles the sound. So, if you like the sound of the rain, let your Contractor know! In this instance, the roof can be installed to enhance the noise you desire.

What Are The Other Benefits of Metal Roofs?

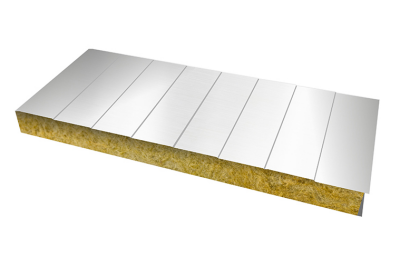

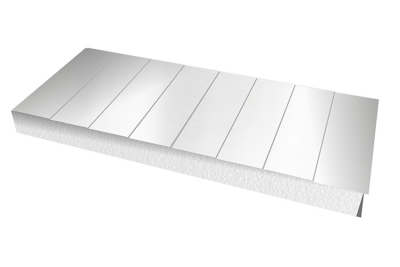

Aside from a quiet nights sleep, owners of metal roofs can enjoy numerous benefits! Heating and cooling amounts to one of the largest expenses homeowners face. Metal roofs, especially those containing a reflective finish or “cooler” color, can reduce the heat absorbed by your home in the summer, while helping the home retain the temperature inside when it’s cooler. Metal roofs also offer a longer lifespan than traditional roofing materials. And when they’ve lived their life? They are still 100% recyclable! Talk about a return on your investment. Pair this with their limitless design capabilities, and you’ve got yourself the perfect roofing material.

Metal roofs are the building material to choose if you want a long-standing foundation that will cost you fewer resources and money over time. Are you interested in learning more about your metal panel options? Contact our qualified team of professionals at 519-451-7663 or info@ecoinsulatedpanels.com.