Picking the right color for your metal roof can be a lengthy process. With countless exciting metal roof colors to choose from, which is best for your home? Should you opt for a darker color or a lighter color? What is best for your region? Remember that with metal roofing, your roof color can help save energy and money over time. Which color should you choose? Let’s find out!

Aesthetics

Before you look into whether your color choice will save you energy and maintenance over time, look at the aesthetics of your neighborhood. Because metal roof colors come in nearly every color under the sun, you can be creative with your choices. However, remember that you will most likely have the same roof for the next several decades. That bright and splashy orange might not be so appealing in ten years.

If you are not sure which color to choose, look at what is common in your neighborhood. You also might need to check in and see if the housing association requires certain standards. Make sure that your roof color complements the style of your home. Avoid clashing colors. Look at all elements like landscaping, windows, shutters, siding, and the doors.

Energy Efficiency

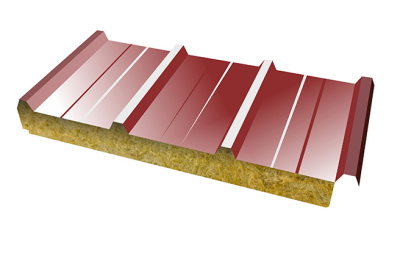

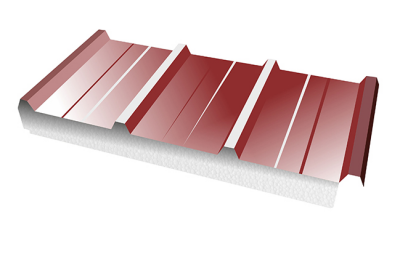

Depending on your location, your roof color can make significant changes to the energy efficiency of your home. For example, light colors like white will reflect sunlight. Homes in hotter climates benefit from this. Use colors like light bronze, peach, beige, white, or light blue if live in a warm climate. You might see your overall air conditioning expenses lower by as much as thirty percent.

Homeowners in cooler regions that have heavily insulated homes do not need to worry about whether they have a darker or lighter roof color. Speak with your roofing contractor about choosing CoolRoof and energy efficient paints for your home. No matter the color you choose, always make sure that you choose the highest quality paint for your roof.