When it comes to maintaining the longevity of your metal roof, upkeep is generally minimal! This high performing, low maintenance roofing material can last 50+ years with the proper care and installation. So to keep your roof “running smoothly” we have composed a streamlined process for checking and maintaining your metal roof – saving you time and money in the future!

Importance of Maintaining Your Metal Roof

Metal roofing is susceptible to scuffing, leaking, denting, degradation, and galvanic corrosion. Regular maintenance, performed a minimum of once per year, can help identify potential problems before they become expensive ones. Hotter, humid climates may need more maintenance than once per year so be sure to keep this in mind. This regular maintenance will not only keep your metal roof looking incredible, but will also extend the longevity of your metal roof!

Surface Maintenance

Surface maintenance can be performed with our without a professional, however you must take extra precautions to ensure your safety. Surface-level maintenance tasks include removing dirt and other harmful elements from the surface of your roof. Start by cleaning out gutters and drains from debris, which can lead to an accumulation of water and premature corrosion. This debris can also get stuck in seams and other “dead spots” on your roof, which can stain or scratch the paint, thereby compromising the panels outer protective layer.

Structural Maintenance

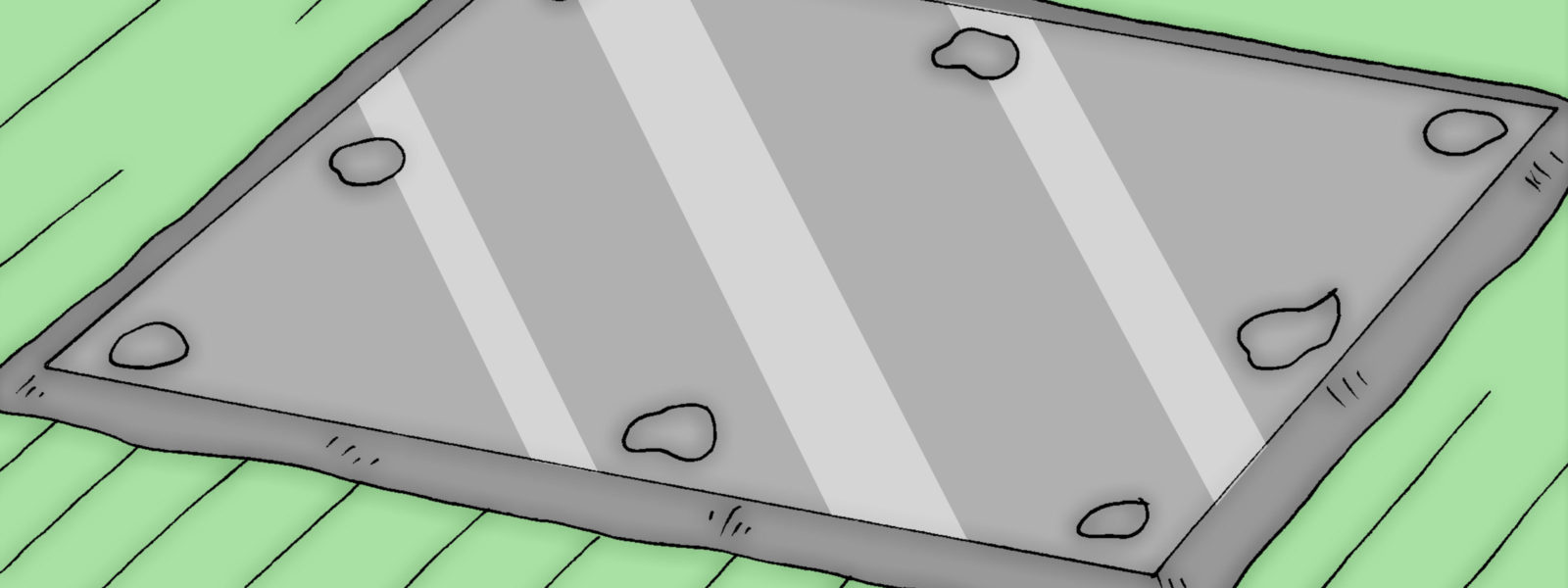

Structural maintenance on your metal roof is more in-depth and should be performed by a qualified professional. Structural maintenance includes checking and/or fixing fasteners, rivets, and screws. These parts attach the panels to the overall structure, so it is important to make sure they are not loose, crooked or missing after the expansion and contraction of the panels over time. Panel seams should also be inspected by a professional at least once per year. Other structural maintenance includes checking and replacing sealant, which prevents natural elements from penetrating the metal roof system.

Are you interested in having a roof that is durable, eco-friendly, low maintenance, AND long lasting? Get in touch with our exceptional team today. We will be happy to make recommendations for your home, and even steer you in the right direction based on your desired style. Contact us at info@ecoinsulatedpanels.com or 1.855.838.9393.